Custom Led Display: Design Process Insights

Have you ever thought of how eye-catching, seamless LED screens that integrate perfectly with the building architecture are made? The LED displays that extend over the edges of the building, form complex architectural shapes, or create immersive environments in luxury venues. The transformation of a brave idea into a dazzling display is a story of the complex and fascinating architectural engineering process. But unlike the quick and easy process of pulling a screen from your warehouse and bringing it on site, the display must capture your vision and integrate into your building. For those of you thinking of your own project, understand that there is a hidden workflow that has been perfected and used on various projects across the globe. That's right. Making a unique customizable screen is a Design and Engineering process that is equally an integrated work of problem solving, artistry, and engineering. Let me take you on a ride through the most important workflow used by experts to create a Design Engineering marvel.

The First Conversation: Unpacking a Vision & its Constraints

The entire process begins with a vision and a challenge. This phase is not technical, but rather focused on deep listening and discovery. This starts with a dialogue between the client and the design team. What is the primary goal? Is it to create a visual masterpiece? To showcase the bold identity of a brand? To enable control room information relay and sharing? To construct a visual retail theatre? At the same time, the physical and environmental realities should be fully appreciated. The designers and engineers need to survey the space, its dimensions, its structural capacity, the ambient light, and the primary sightlines. Then, they explore vital logistical questions: where are the power and data infrastructure access? What are the sight distances and therefore the required level of image detail? This phase is foundational. An aligned and mutual understanding of the artistic vision and practical constraints will make certain that the following custom design of the LED display will be brilliant, dependable, and right for its intended site.

From Concept to Blueprint: Creative and Technical Fusion

By knowing the 'why' and 'where' , the process can seamlessly move into Solution Design. Here, the creative and technical converge. The design team begins turning the vision into initial design concepts, eventually employing sophisticated 3D modeling and rendering to simulate the various shapes, sizes, and curvatures that the screens might take on in the actual environment. At this stage, the technical decisions fit the design the most. The selection of pixel pitch (the distance between clusters of LEDs) is key to determining whether the image is of the desired resolution based on the distance the viewer is standing from the screen and whether the screen is within budget. For optimal crispness, a viewer should be at a distance of a couple of meters from the screen, and at twenty meters, the image should be perfectly visible. The type of product is also determined by the environment. For instance, a studio and boardroom require fine pitch, color-accurate modular panels, while outdoor landmark façade installations require rugged, high-brightness modules. The structural design also plays a big role. How will the display be supported? Will it need a custom frame, a hanging system, a motorized rig if movement is required, or something else? The output of this is a full blueprint, correct down to a high resolution render and complex schematics that clearly define the scope of the project, and therefore, align everyone's expectations before any hardware is made.

Engineering and Validation: Making Sure It Works

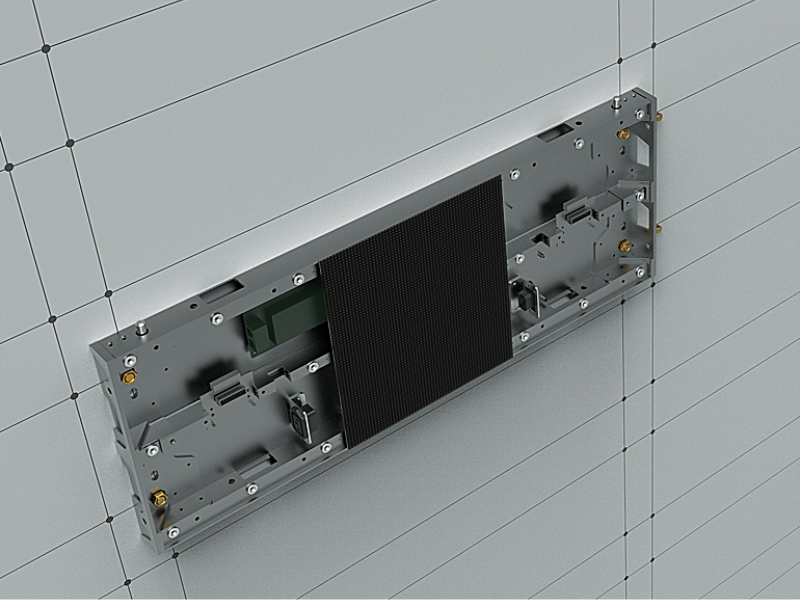

Now that we have finished the design and testing phase, the next step is to manufacture the LED display. This process can take a long time. First, the virtual model undergoes a series of stress tests to check its durability and functionality. Then, engineers work on thermal model tests that ensure the electronic components do not overheat. Then, the engineers have to design the circuitry power to give the display the power and data it needs, and manage signal distribution among its multiple components. At this step engineers have to do a lot of mechanical engineering to make sure the design can be manufactured to fit together easily and that they have sufficient room to do so. Then they should make mechanical provisions to assist with the installation. Critical steps here include the manufacture and testing of a small functional model. This states are a champion of the concept, and often do conceptually with the design, and validate the display with the concept technology before manufacture. To ensure flawless performance throughout the entire life of the display, the engineers put in place very detailed instructions built on years of experience, to ensure every module and component meets the required standards.

Realization and Refinement: Bringing the Vision to Life

The final step is the onsite Realization and Refinement of the display. This stage transforms the conceptual project into an actual living visual centerpiece. Construction teams deploy the design with the modular system according to the engineered plans and with great care. Their skill is especially important in any complex final installation, whether in a busy public plaza or an enclosed television studio. Once the system is mounted, connected and fully constructed, the installation is complete. The system undergoes a full commissioning process. Technicians adjust and balance the display system to ensure all sections match in color and brightness to avoid any distractions from the content. The ease of content and schedule management is final tested and controlled. However, the transition to post-handover processes should not be the end of the process. The hallmark of a professional provider is the continuous assistance and enhancements offered, including, but not limited to, thorough training of the operators, software updates, and maintenance. The objective is to support and maintain the custom LED display to ensure the client continues to utilize the asset well beyond the initial launch.